Since 2018 I have been working in Demand Driven. I was the Product Manager for DDMRP Solutions and I managed the global rollout of DDMRP in Etex (200+ plants, 300+ users, 45000+ buffers). My responsibilities encompassed the development of DDMRP, the creation of the interface with SAP, the configuration of b2wise, the deployment to over 120 factories, the creation of an e-learning environment, the training and coaching of over 150 planners, and the implementation of Power BI Dashboards for Demand Driven S&OP.

In recognition of this work, I was endorsed as a Demand Driven Supply Chain Professional (DDSCP). The complete Etex case study including a video is here (search with keyword Etex). In 2022 this project was nominated for the prestigious Etex CEO Award.

“The DDSCP™ is a fellowship level endorsement from the Demand Driven Institute. The Demand Driven Supply Chain Professional™ (DDSCP) has proven the ability to successfully apply Demand Driven concepts at the operational and tactical levels creating sustained value for an enterprise through that application. It represents the highest level of Bloom’s Taxonomy – Create.”

I have a strong background in consulting in the area of Supply Chain Management. Since 1994 I have worked as SAP consultant, implementing solutions in the area of production planning and scheduling, shop floor control, demand management, supply and network planning, warehouse management and quality management. Some of my main customers include Etex, BP, CRH, NXP Semiconductors, Philips Electronics, Essent, Enexis, Fuji and Hoogovens.

Using my 30+ years of experience I can provide the following consulting services:

- Value Stream Mapping

- Design your Demand Driven Operating Model

- Prototype DDMRP

- Implement DDMRP

- Finetune and improve your DDMRP implementation

- Design the interface with your ERP system

- Coach DDMRP Planners

- Implement Demand Driven S&OP

- Design and Implement Demand Driven KPI’s

- ..

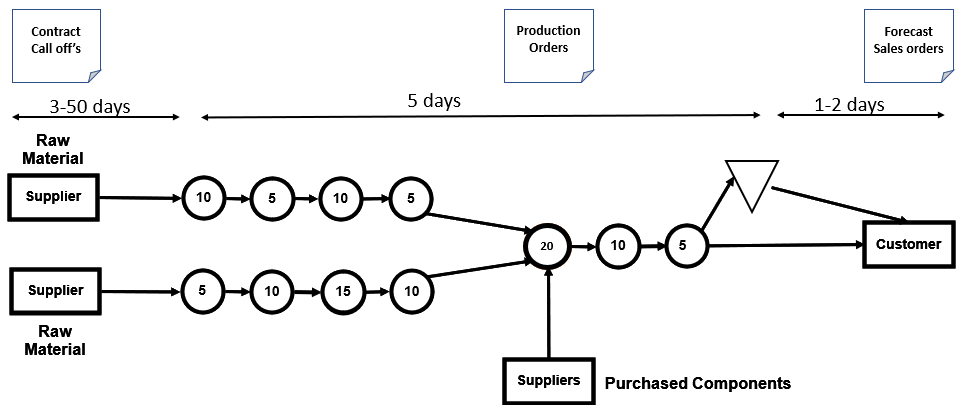

Value Stream Mapping

In a Value Stream Map we analyze and visualize your supply chain. It has three main components: the flow of materials, the flow of information and the corresponding timelines. Here’s an example.

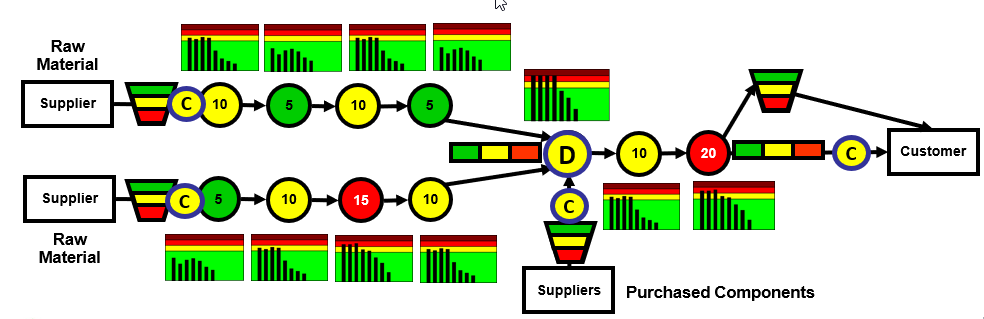

Design your DDOM

A DDOM is a supply order generation, operational scheduling and execution model that uses actual demand in combination with strategic decoupling and control points and stock, time and capacity buffers. The goal is to create a system that promotes and protects the flow of relevant information and materials within the operational relevant range (hourly, daily and weekly). Here’s an example:

Prototype DDMRP

This service includes data collection, mapping in a software tool (can be Excel), basic configuration of the buffers, resulting stock levels plus a report. This is a good way to explore the potential savings and to prove DDMRP, at minimal investment.

Implement DDMRP

Using our extensive practical experience we can take ownership of the implementation of DDMRP. Important aspects are: how to integrate DDMRP in your existing processes for supply chain planning, your ERP system, data collection, phased go live approach, training of the stakeholders, change management and managing the business case.

Finetune and improve your DDMRP implementation

The buffers in a DDMRP implementation are never static. The world is changing all the time (VUCA world) so it is important to implement a process for continuous improvement. Although in the Demand Driven philosophy “roughly right” is good enough there is always room for finetuning and improvement. Examples are more refined “buffer profiles”, challenge Minimum Order Quantities, implement reason codes etc.

Design the interface with your ERP system

An automated, bidirectional interface with your ERP system is a conditio sine qua non for a successful DDMRP implementation. Using our 30+ year experience we can design this interface for you.

Coach DDMRP Planners

In the first period after go live it is important to monitor the order compliance: to what extent do planners accept the replenishment proposals of the DDMRP solution. If the order compliance is not (nearly) perfect this will result in repeated manual work but also the tactical process of DD S&OP is built on wrong data.

We can coach your DDMRP planners, run additional training and help them understand the planning and execution alerts of the DDMRP solution. Additional fine-tuning of the buffers may be needed as well.

Implement Demand Driven S&OP

Once the Demand Driven Operation Model is in place and the order compliance has reached a sufficiently high level, your organization is ready for the next step: the tactical process of Demand Driven Sales and Operations Planning. DD S&OP is the tactical, bidirectional integration point in a Demand Driven Adaptive Enterprise. Operating primarily in the tactical relevant range, DDS&OP maintains and updates the parameters of the DDOM based on current and emerging business strategy supplied by Adaptive S&OP and the systematic review of past and projected DDOM performance. DDS&OP evaluates scenarios proposed in the Adaptive S&OP process in order to provide relevant DDOM projections. Additionally, DDS&OP recommends strategic alterations and/or internal innovations to leadership involving

DDOM future capability and performance.

Design and Implement Demand Driven KPI’s

An efficient DD S&OP process needs flow based KPI’s, tailored to your organization and to your specific requirements. A lot of the required information will come from the Demand Driven Operating Model but in most cases it will have to be enriched with company specific data.

Using our extensive experience and starting from a library of predefined KPI’s we can help you analyze the information, create an information model and implement specific visualizations, e.g. using Power BI.